Micro etching in Oak Harbor, Ohio, is a cutting-edge manufacturing process that carves intricate patterns onto transparent materials with unmatched precision. This technique benefits various industries by enhancing aesthetics, improving functionality, and enabling the integration of microsensors for advanced applications in healthcare, electronics, and beyond. The meticulous process involves preparing the material, masking specific areas, etching the desired pattern, and removing the mask to reveal detailed microstructures suitable for diverse, innovative uses.

“Unleash the power of precision with micro etching, a revolutionary technique transforming transparent materials in Oak Harbor, Ohio. This advanced method goes beyond traditional fabrication, offering unprecedented control over material properties. From enhancing optical clarity to creating intricate patterns, the benefits are vast. Learn how micro etching works its magic, exploring the step-by-step process and uncovering why it’s becoming an indispensable tool in various industries. Discover the advantages that make it a game-changer for transparent material applications.”

- What is Micro Etching and How Does it Work?

- Benefits of Micro Etching for Transparent Materials

- Micro Etching Process: A Step-by-Step Guide (Oak Harbor, Ohio)

What is Micro Etching and How Does it Work?

Micro etching is a precise and advanced manufacturing technique that involves the controlled removal of material from a surface at a microscopic level. This process is particularly effective for transparent materials, allowing for the creation of intricate patterns, structures, and designs that are not achievable through traditional machining methods. In Oak Harbor, Ohio, where precision engineering is highly regarded, micro etching has become a game-changer across various industries.

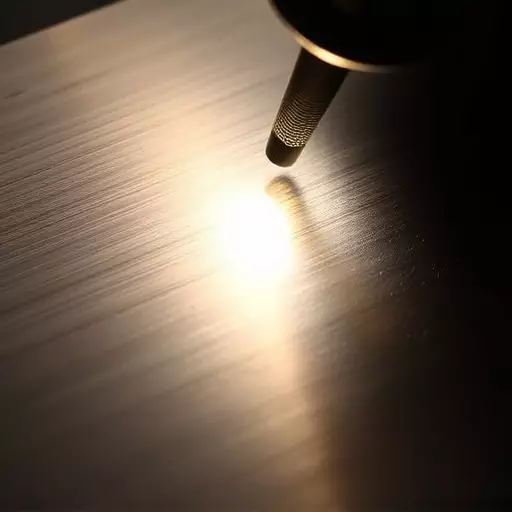

The micro etching process utilizes specialized equipment, such as electron beam (EB) or ion beam (IB) systems, to direct a high-energy beam onto the surface of the transparent material. This energy etches away a precise amount of material, creating patterns down to the nanometer scale. The benefits of micro etching are numerous; it offers unparalleled precision, enabling the production of tiny features and intricate structures. This technique is ideal for manufacturing components used in electronics, optics, healthcare, and aerospace applications, where size and accuracy matter most.

Benefits of Micro Etching for Transparent Materials

Micro etching for transparent materials offers a multitude of benefits, making it a preferred technique in various industries. The precision and control inherent in the micro etching process allow for the creation of intricate patterns and structures on glass, plastics, and other transparent substrates. This level of detail is crucial for enhancing visual aesthetics, improving functionality, and enabling advanced applications.

In Oak Harbor, Ohio, and beyond, the benefits of micro etching are widely recognized. It enables the development of smarter devices with improved optical properties, such as enhanced transparency and anti-reflective coatings. Moreover, it facilitates the integration of microsensors and microfluidic channels into transparent materials, opening up possibilities for innovative medical devices, advanced displays, and more. This versatile technique is a game-changer in transforming raw transparent materials into sophisticated components with unparalleled performance.

Micro Etching Process: A Step-by-Step Guide (Oak Harbor, Ohio)

The micro etching process in Oak Harbor, Ohio, involves a series of meticulous steps to create intricate patterns and designs on transparent materials like glass or polymer sheets. This advanced technique has gained prominence due to its benefits of micro etching, which include enhanced aesthetic appeal, improved functionality, and increased durability for finished products. The process begins with the preparation of the material surface, ensuring it’s free from contaminants and properly secured in place. Next, a mask, often made of photoresist or other specialized materials, is precisely applied to protect certain areas of the substrate while exposing others to be etched away.

After the mask is in place, an etchant—a chemical solution capable of removing the desired material—is introduced and allowed to react with the exposed regions. The etchant gradually carves out the pattern, creating microscopic features or textures as per the designed specifications. Once etching is complete, the mask is carefully removed, revealing the intricate microstructure of the material’s surface. This meticulous process allows for the creation of incredibly detailed patterns, opening up possibilities for innovative applications in fields like optics, electronics, and even artistic craftsmanship.