The micro etching process in Oak Harbor, Ohio, is a specialized technique for precise material manipulation at a microscopic level, offering significant advantages like enhanced finish, superior precision, and intricate design capabilities. It's crucial in modern technology, benefiting electronics, pharmaceuticals, and aerospace industries. This method faces challenges due to its precision but can be optimized with advanced control systems, cleanroom environments, and tool maintenance. Engaging in micro etching workshops demands safety precautions, including PPE, good ventilation, strict protocols, and regular equipment maintenance. Advanced techniques like wet chemical etching and DRIE further enhance material removal control, opening new possibilities for modern technology.

Discover the precision art of micro etching with our comprehensive guide tailored for Oak Harbor, Ohio residents. From understanding the intricate micro etching process to unlocking its remarkable benefits, this article is your go-to resource. Learn about common challenges and effective solutions, ensuring optimal performance from your micro etching tool. Explore safety precautions, advanced techniques, and practical tips to elevate your skills. Uncover why micro etching is a game-changer in various industries.

- Understanding Micro Etching: A Comprehensive Overview

- The Micro Etching Process: Step-by-Step Guide for Oak Harbor Ohio Residents

- Unlocking the Benefits: Advantages of Micro Etching Techniques

- Common Challenges in Micro Etching and How to Overcome Them

- Maintenance Tips: Ensuring Optimal Performance of Your Micro Etching Tool

- Safety Precautions and Best Practices for Micro Etching Workshops

- Advanced Techniques to Enhance Your Micro Etching Skills

Understanding Micro Etching: A Comprehensive Overview

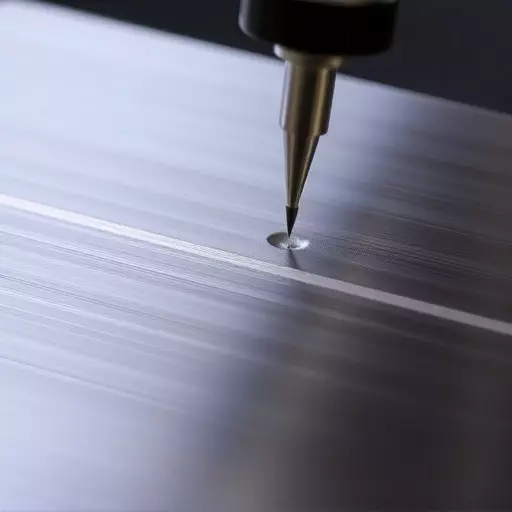

Micro etching, a specialized process, involves the precise removal or addition of materials at a microscopic level, typically using plasma or chemical reactions. This advanced technique is central to many modern technologies, enhancing components for improved performance and functionality. The benefits of micro etching are vast, from enabling the creation of intricate microstructures to enhancing surface properties like hardness, smoothness, and adhesiveness. In Oak Harbor, Ohio, professionals leverage the micro etching process to cater to diverse industries, including electronics, pharmaceuticals, and aerospace, showcasing its versatility and importance.

This meticulous approach demands precise control and specialized equipment to ensure optimal results. By understanding the micro etching process, technicians can navigate the intricate steps, from mask design and material selection to etch parameters and post-processing, to deliver high-quality outcomes. The advantages extend beyond technical capabilities; micro etching contributes significantly to product innovation, ensuring devices operate at peak efficiency while meeting stringent industry standards.

The Micro Etching Process: Step-by-Step Guide for Oak Harbor Ohio Residents

The micro etching process involves the precise removal or addition of tiny amounts of material on a microscopic scale. For Oak Harbor Ohio residents looking to harness its potential, here’s a simplified step-by-step guide. It begins with preparing the surface, ensuring it’s clean and free from contaminants. Next, a specialized etchant is applied, which chemically reacts with the target material, etching away precise patterns or structures. The key lies in controlling factors like time, temperature, and etchant concentration to achieve desired results without damaging the substrate.

This meticulous process offers numerous benefits, including enhanced surface finish, improved precision, and the ability to create intricate designs that wouldn’t be possible with conventional machining methods. Whether for manufacturing components, creating artistic engravings, or even in medical applications, micro etching provides Oak Harbor residents with a powerful tool to achieve microscopic precision tailored to their needs.

Unlocking the Benefits: Advantages of Micro Etching Techniques

The world of precision manufacturing and material modification has seen a significant advancement with the introduction of micro etching techniques. This highly specialized process, available at top-tier facilities like those in Oak Harbor, Ohio, offers a multitude of benefits that revolutionize various industries. By employing controlled etchant solutions and precise hardware, micro etching allows for the creation of intricate patterns, structures, and features on a microscopic scale—something once thought impossible.

This advanced method has numerous advantages, including improved material properties, enhanced surface finishing, and the ability to create complex 3D topographies. In electronics, micro etching plays a pivotal role in fabricating tiny components and circuits, enabling smaller, faster, and more energy-efficient devices. Similarly, in medical device manufacturing, it facilitates the production of precise instruments with intricate details, contributing to better patient outcomes. The versatility and precision inherent in micro etching techniques make it an indispensable tool for modern industries, pushing the boundaries of what’s achievable in material modification.

Common Challenges in Micro Etching and How to Overcome Them

The micro etching process in Oak Harbor, Ohio, presents unique challenges due to its precision and intricate nature. One common difficulty is achieving consistent etch depth, especially when dealing with complex patterns. This issue can be overcome by employing advanced control systems that monitor and adjust etching parameters in real-time, ensuring accurate results. Regular calibration of the equipment is also crucial for maintaining optimal performance.

Another challenge lies in preventing unwanted side effects like material contamination or pattern distortion. To address this, cleanroom environments are essential, where proper filtration systems and controlled conditions minimize particle accumulation. Additionally, using high-purity etchant solutions and implementing rigorous quality control measures help ensure the benefits of micro etching, such as enhanced surface finish and precise feature definition, are consistently achieved.

Maintenance Tips: Ensuring Optimal Performance of Your Micro Etching Tool

Maintaining your micro etching tool is crucial for ensuring optimal performance and prolonging its lifespan. Here are some essential tips to keep in mind when taking care of your micro etching device, especially if you’re based in Oak Harbor, Ohio, where precision manufacturing is a significant industry. Regular cleaning and calibration checks are paramount to prevent build-up and ensure accurate results. Use suitable cleaning solutions specifically designed for micro etching equipment to remove any residue or debris without damaging the tool.

Additionally, consistent monitoring of tool performance during the micro etching process is vital. Keep an eye on etch rates, pattern integrity, and gas flow dynamics. Regular maintenance not only optimizes the efficiency of your micro etching process but also extends the lifespan of your equipment, thereby reducing downtime and associated costs. Remember, a well-maintained micro etching tool in Oak Harbor, Ohio, can deliver superior results, enhance precision, and ultimately contribute to the benefits of micro etching technology.

Safety Precautions and Best Practices for Micro Etching Workshops

Engaging in micro etching workshops requires a keen awareness of safety precautions and best practices to ensure a smooth and successful experience. First and foremost, given the intricate nature of the micro etching process Oak Harbor Ohio, all participants should be provided with appropriate personal protective equipment (PPE), including goggles, gloves, and lab coats. These prevent direct contact with etchant chemicals and minimize exposure to potentially harmful fumes. Workshops should also maintain a well-ventilated environment, using fume hoods or other exhaust systems to remove hazardous vapors.

Best practices in micro etching workshops include strict adherence to protocol. Each participant should receive clear instructions on chemical handling, waste disposal, and emergency response procedures. Regular cleaning and maintenance of equipment are vital to prevent contamination and ensure the benefits of micro etching are realized. Additionally, fostering a culture of safety through communication and training can significantly reduce risks, making workshops more productive and enjoyable for all involved.

Advanced Techniques to Enhance Your Micro Etching Skills

The micro etching process in Oak Harbor, Ohio, is a precise and advanced technique that goes beyond basic etchings. To elevate your skills, explore specialized methods such as wet chemical etching and deep reactive-ion etching (DRIE). These advanced techniques offer unparalleled control over material removal, enabling you to achieve intricate patterns and structures at microscopic levels.

Understanding the benefits of micro etching is key. It enhances product performance by improving surface characteristics, enabling better adhesion and smoothness. In industries like semiconductor manufacturing and medical device production, micro etching ensures precision and reliability. By adopting these advanced techniques, you can unlock new possibilities in your work, catering to the ever-demanding needs of modern technology.